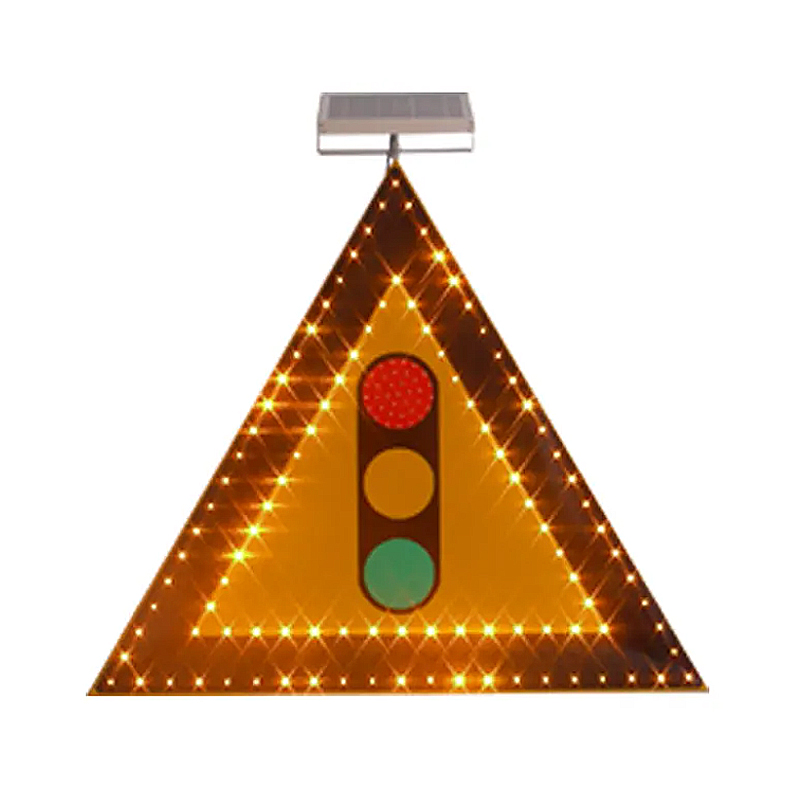

Attention To Signal Light Sign

Attention to Signal Light Sign is important for several reasons:

A. Safety:

It helps to remind drivers to pay attention to traffic signals, reducing the likelihood of accidents at intersections.

B. Traffic flow:

By prompting drivers to be alert to signal lights, the sign contributes to smoother traffic flow and reduces congestion at intersections.

C. Compliance with regulations:

It serves as a visual reminder for drivers to adhere to traffic signals, ensuring they follow traffic laws and signals.

D. Pedestrian safety:

It also benefits pedestrians by encouraging drivers to be attentive to traffic signals, thus enhancing safety at crosswalks and intersections.

| Size | 700mm/900mm/1100mm |

| Voltage | DC12V/DC6V |

| Visual distance | >800m |

| Working time in rainy days | >360hrs |

| Solar panel | 17V/3W |

| Battery | 12V/8AH |

| Packing | 2pcs/carton |

| LED | Dia <4.5CM |

| Material | Aluminum and galvanized sheet |

A. Design: The process begins with the creation of the sign's design, which includes the layout of the text, graphics, and any relevant symbols. This design is often created using computer-aided design (CAD) software and may need to comply with specific regulations and standards for traffic signs.

B. Material selection: The materials for the sign, including the sign face, aluminum backing, and frame, are selected based on factors such as durability, visibility, and weather resistance. The choice of materials is important to ensure the sign can withstand outdoor conditions and maintain its visibility over time.

C. Solar panel integration: For solar-powered signs, the integration of solar panels is a critical step. This involves selecting and installing solar panels that can efficiently capture and convert sunlight into electrical power to illuminate the sign's LEDs.

D. LED assembly: The assembly of LEDs (light-emitting diodes) involves mounting the LED lights onto the sign face in accordance with the design specifications. The LEDs are typically arranged to form the text and graphics of the sign, and they are connected to the solar panel and battery system.

E. Wiring and electrical components: The electrical wiring and components, including a rechargeable battery, charge controller, and associated circuitry, are integrated into the sign to manage the power supply from the solar panel and store energy for nighttime illumination.

F. Quality control and testing: Once the sign is assembled, it undergoes rigorous quality control checks and testing to ensure that all components are functioning properly, the LEDs are illuminated as intended, and the solar-powered system is operating efficiently.

G. Installation hardware: In addition to the sign itself, there is a need for installation hardware such as mounting brackets, poles, and associated hardware for securing the sign in its intended location. Throughout the manufacturing process, attention to detail, adherence to industry standards, and quality control measures are crucial to producing durable, reliable solar traffic signs that meet regulatory requirements and contribute to safe and efficient traffic management.

Q1: What's your minimum order quantity?

We don't have MOQ required, even if you only need one piece, we will produce it for you

Q2: What's your delivery time?

Normally, 20 days for container orders.

Q3: Can I have free samples?

Yes, we can provide samples at a small price like A4 size free of charge. You may just need to take the shipping cost

Q4: What payment terms can you accept?

Most of our customers would like to choose T/T, WU, Paypal, and L/C. Of course, you also can choose to pay through Alibaba.

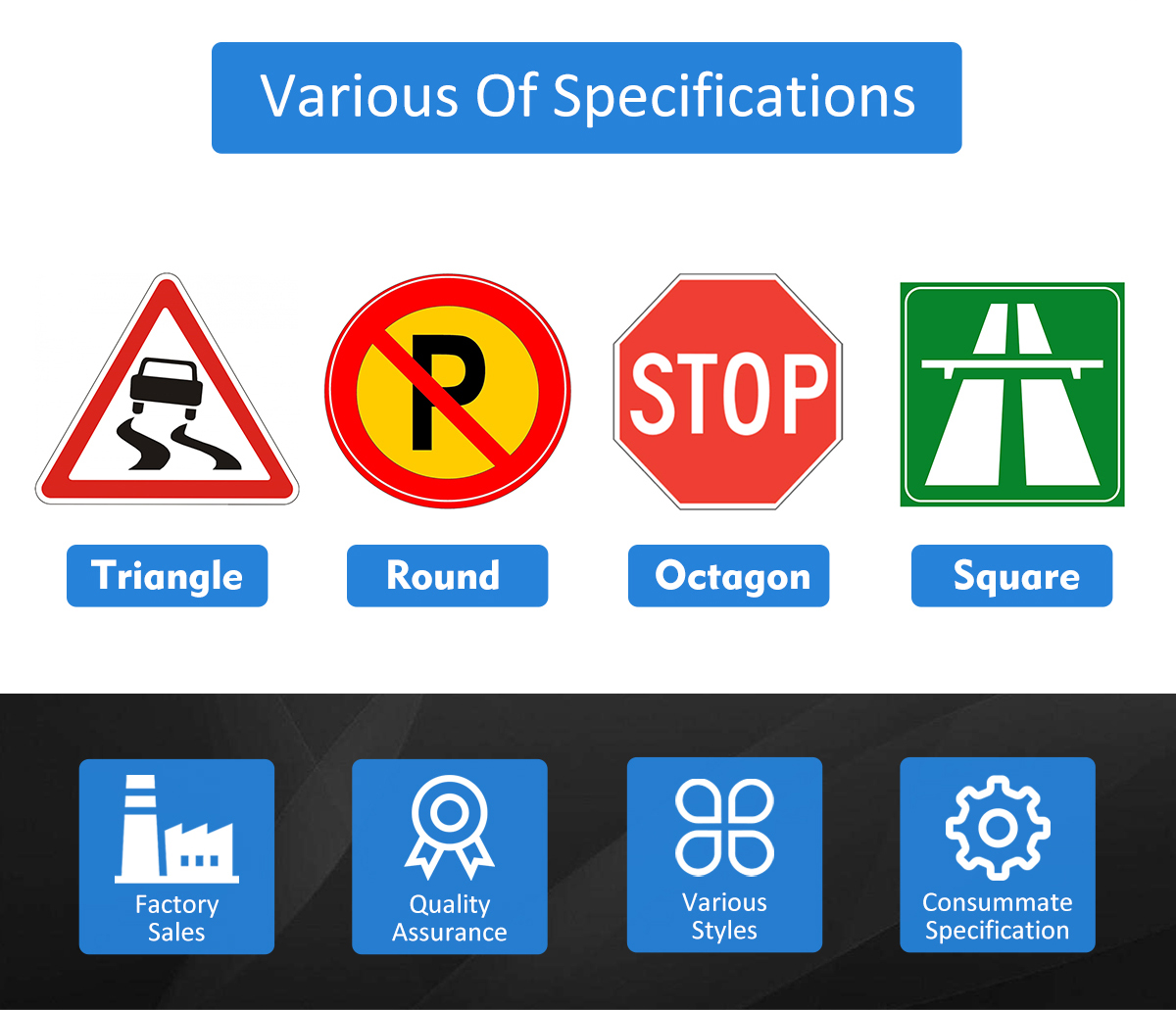

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top